In the country of Iran, diesel generating sets are widely used for power generation. One of our clients operates multiple diesel generator sets at various locations across Tehran, Iran. These generators are typically run continuously for several days, except during scheduled preventive maintenance.

Caterpillar G3616 Crankshaft

The Caterpillar G3616 gas engine met with an accident and, upon preliminary inspection, was found to be damaged.

|

|

|

RA Power Solutions’ technicians arrived at the site near Tehran and inspected the crankshaft of the Caterpillar G3616. The following are the main observations:

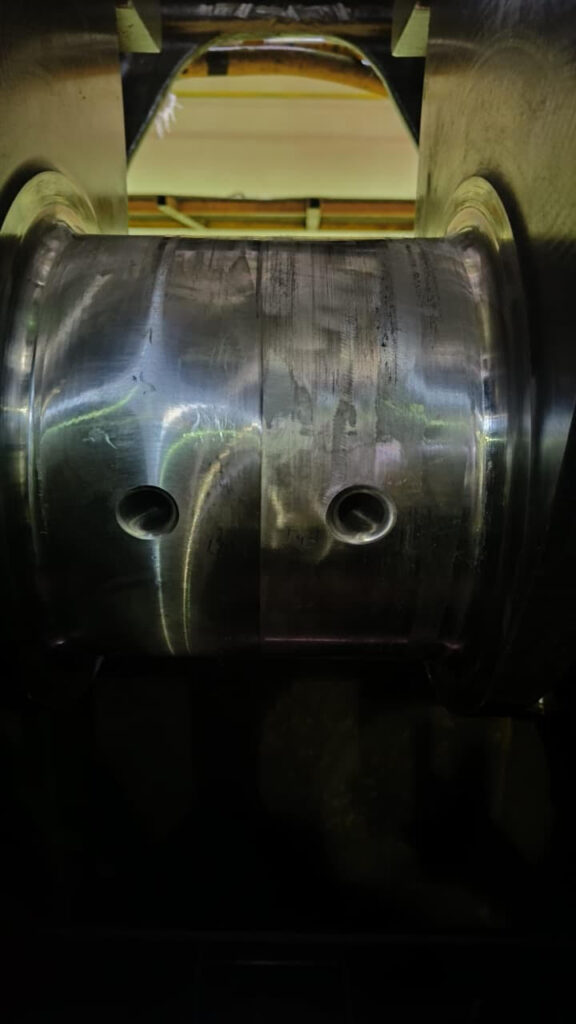

(i) The crankpin bearing of Number #03 was severely stuck to the crankpin surface. The top layer of the bearing had melted and become embedded in the crankpin diameter.

(ii) The bearing material embedded in the crankpin surface was removed to facilitate inspection for hardness, presence of cracks, and dimensional accuracy.

(iii) The minimum and maximum crankpin diameters observed are as follows:

(a) Minimum diameter: 214.93 mm

(b) Maximum diameter: 216.00 mm

Against the standard diameter of 216.00 mm, an ovality of 1.07 mm was observed

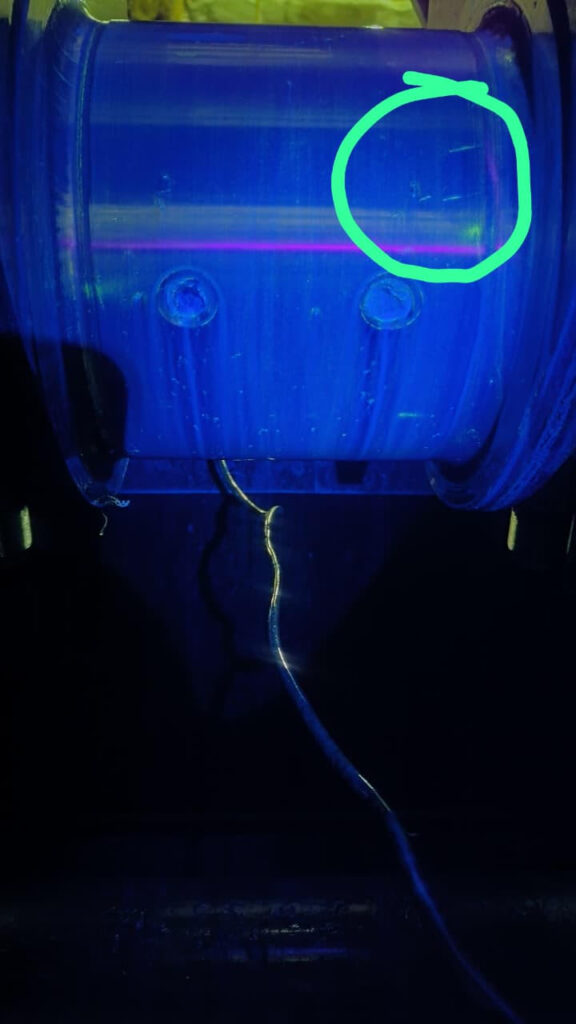

(iv) Minor surface cracks were also observed during the MPI (Magnetic Particle Inspection).

(v) Hardness was found to be within acceptable limits, except at a few spots.

|

|

|

Saving of Caterpillar G3616 Crankshaft From Rejection

Based on the fact that the ovality in crankpin number #03 was observed to be 1.07 mm, an inquiry was sent to the manufacturer. The manufacturer informed us that the maximum allowable undersize for the crankpin is 1.00 mm, meaning the minimum acceptable diameter must be 215.00 mm. In this case, since the damage had already reached 1.07 mm, the crankshaft is considered rejected, as per the manufacturer’s guidelines. In this case, the expected undersize after grinding was 2.00 mm, which is beyond the permissible limit.

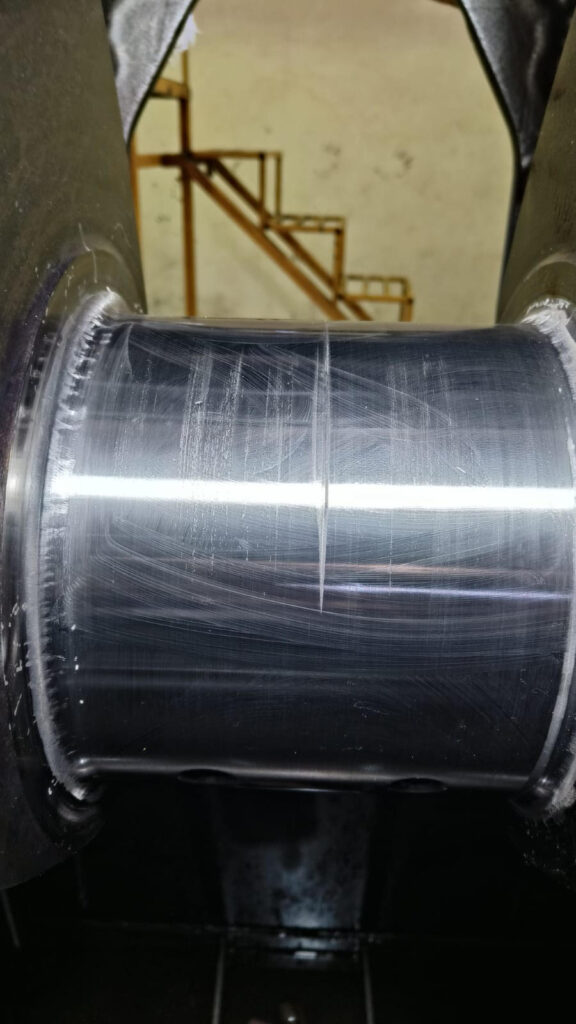

RA Power Solutions has undertaken onsite grinding of Crankpin Number #03, reducing its size by 2.00 mm, and the following dimensions were maintained after grinding:

a) Minimum diameter observed: 213.98 mm

b) Maximum diameter observed: 214.00 mm

|

|

RA Power Solutions, a company providing services for the past 45 years, arranged a 2.00 mm undersized bearing for the Caterpillar G3616 crankshaft through a leading manufacturer based in Germany.

The engine has been assembled and is performing satisfactorily.

We have been regularly executing the on site crankshaft repairs and crankshaft grinding of different engines, like Caterpillar, Wartsila, Cummins, Yanmar, Daihatsu and MAN and MAK in Iran, Iraq, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, and Fujairah, Bahrain, Kuwait, Iraq, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more information regarding crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.