It is generally observed that it is difficult to undertake grinding and repair of crankshaft having a smaller diameter of crankpin and main journal. The bearing width length also plays a very important role in the successful onsite grinding of the crankshaft with the small diameter and bearing width. It is very difficult to prepare tooling and equipment that can be placed on the crankpin diameter and grinding can be executed.

RA Power Solutions with experience of more than four decades in the repair of crankshafts of high-capacity engines has the advantage of designing and manufacturing the onsite crankshaft grinding equipment. We manufacture the onsite crankshaft grinding machine diameter ranging from 35 mm to 700 mm whereas most of the crankshaft grinding companies based in Europe, Singapore, UK do not have the equipment which is designed to undertake the grinding and polishing of crankpin and the main journal having a small diameter and bearing length.

We were approached by one of the leading shipping companies based in Europe advising about the damage of the crankshaft due to the failure of the lubricating oil pump of Daihatsu 5DC-17.Engine.

The details of the engine, crankpin diameter, and bearing width are given below

| S.NO | Crankshaft Details | |

| 1. | Engine Make | Daihatsu |

| 2. | Engine Model | 5DC-17 |

| 3. | Crankpin Diameter Standard | 145mm |

| 4. | Crankpin Bearing Width | 76 mm |

| 5. | Name of Vessel | MV BULK |

RA Power Solutions technicians having valid Indian seaman books boarded the vessel at Hamburg port.

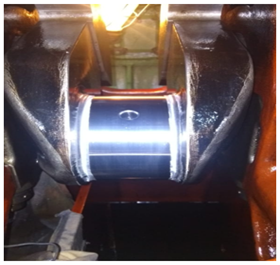

Following were the main observations of the crankpin of Daihatsu 5DC-17

- No inspection can be carried out as the bearing metal was stuck on the crankpins.

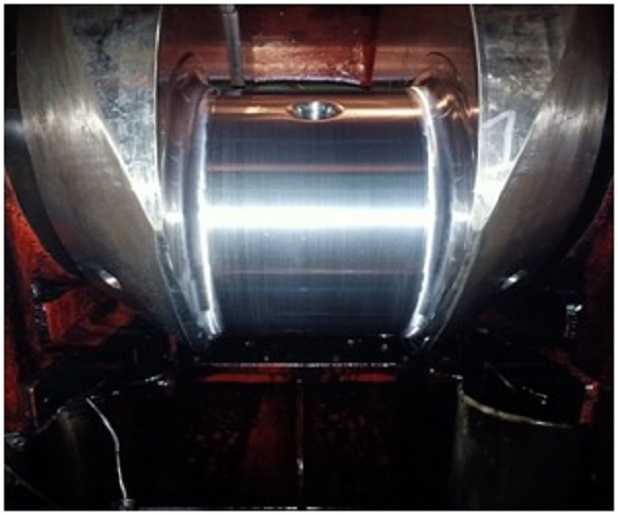

- The bearing metal was removed from all the crankpins by polishing them with the fine grinding media which is normally carried by our technicians.

- All the crankpin’s hardness was checked and was observed within limits. No crack was observed during the MPI inspection by high-intensity ultra-violet torch.

- The ovality and damage except for crank pin no. 3 was observed up to 0.6 mm and for crankpin no. 3 it was 1.26 mm.

- On going through the above readings and the manufacturer’s manual since the crankpin no. 3 was damaged beyond the last limit of 1.20 mm. The crankshaft was rejected.

- In this time of recession which shipping industries are going through, the owners requested RA Power Solutions to undertake the refurbishment of the crankshaft and save the crankshaft from rejection as they cannot afford to buy a new crankshaft costing in the range of 40,000 to 45,000 US dollar.

Action taken by RA Power Solutions to save the crankshaft of Daihatsu 5DC-17

- Since all other important parameters like hardness, and no traceability of crack, RA Power Solutions repaired the crankshaft by maintaining the following dimensions of the crankpin.

- All the crankpins except crankpin no. 3 were undersized by 0.8 mm.

- Crankpin no. 3 having the ovality and damage to the extent of 1.26 mm was reduced to 1.60 mm under the deviation.

- All the crankpins were polished by the special polishing media and readings were recorded.

Supply of undersize bearings for Daihatsu 5 DC -17

RA Power Solutions Pvt. Ltd. arranged the undersize bearings of 0.8 mm and bearings of 1.6 mm undersize. With these bearings supplied by RA Power Solutions, the engine was assembled and load trials were taken. This job was executed in November 2019 and the engine is performing satisfactorily.

Don’t reject the crankshaft, contact RA Power Solutions for advice.

- We appeal to the engineers and owners of shipping companies having industries and power plants not to reject the crankshaft.

- RA Power Solutions with experience of four decades has the technology and equipment to save the crankshaft from rejection which is even discarded by the engine manufacturer. Use our experience and equipment to save the crankshaft.

- We stand guarantee for all the repairs executed by us.

- The availability of undersized bearings or special-size bearings which are not available from the engine manufacturer is supplied by us to put back the engine into operation after refurbishing the crankshaft.

Conclusion:

In the case of the crankshaft of Daihatsu 5DC-17, the crankpin diameter is only 145 mm and the bearing width is 76 mm. Most of the crankshaft repair companies do not have the necessary tooling to repair of crankshaft of Daihatsu with a small diameter and bearings width. Hence, they recommend taking it to the workshop or replacing it with a new one. Don’t get carried away and contact RA Power Solutions having successfully executed the repair of more than 10,000 crankshafts all over the world.

For more information regarding the repair of the crankshaft of Daihatsu, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.