crankshaft

1 Jun , 2023

0 Comments

RA Power Solutions undertakes onsite repair of compressor crankshafts for all applications.

Compressor Crankshafts are generally repaired by the following

- Air compressor

- Reciprocating compressor

- Hydrogen compressor

- Ammonia compressor

- Turbo Compressor

- Centrifugal Compressor

- Axial Compressor

- Screw Compressor

- Refrigeration compressor

No requirement for the disassembly of the compressor and removal of the compressor crankshaft. With the latest technology and equipment available for onsite repair of the crankshaft, there is no requirement of even disassembly of the compressor for the repair of the crankshaft to repair the compressor crankshaft. Our technicians with portable onsite compressor crankshaft repair equipment visit your site all over the world.

The damaged Compressor Crankshaft is thoroughly inspected by our experienced technicians mainly for the following parameters

- Dimensional inspection of crankpin for taper and ovality.

- Inspection of hardness.

- Inspection of crankpin for crack detection by MPI or dye penetrant test.

- Deflection for checking the alignment.

- Visual inspection.

Execution repair of compressor crankshaft grinding on-site

- After undertaking the inspection of the damaged compressor crankshaft, our technicians plan a strategy to repair it onsite.

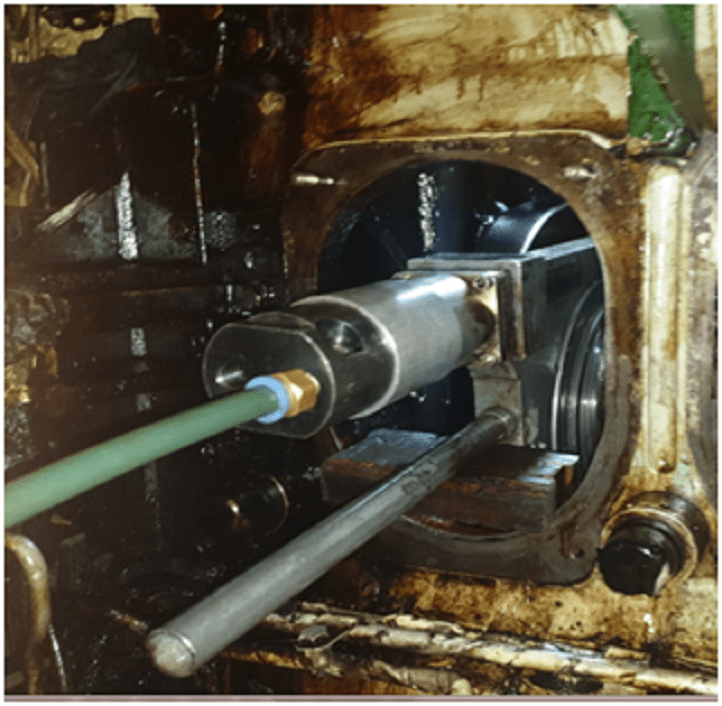

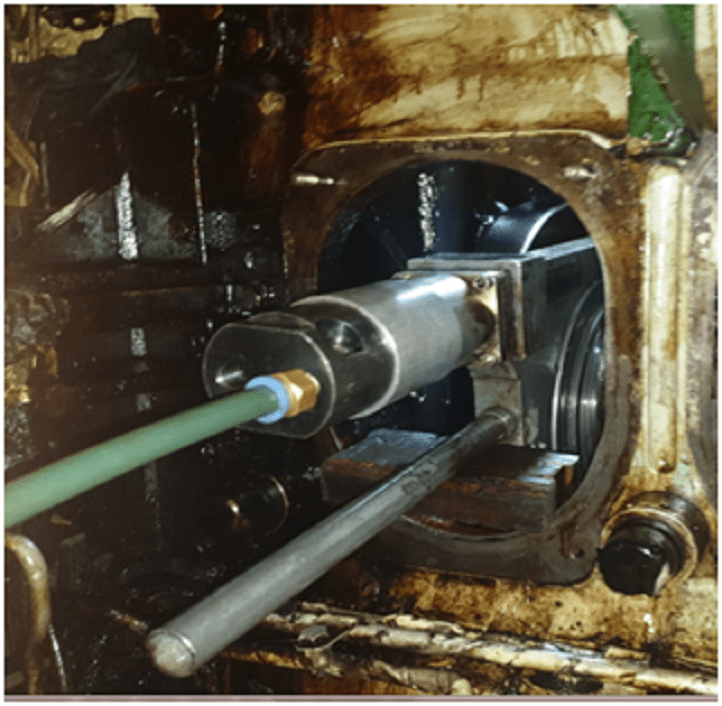

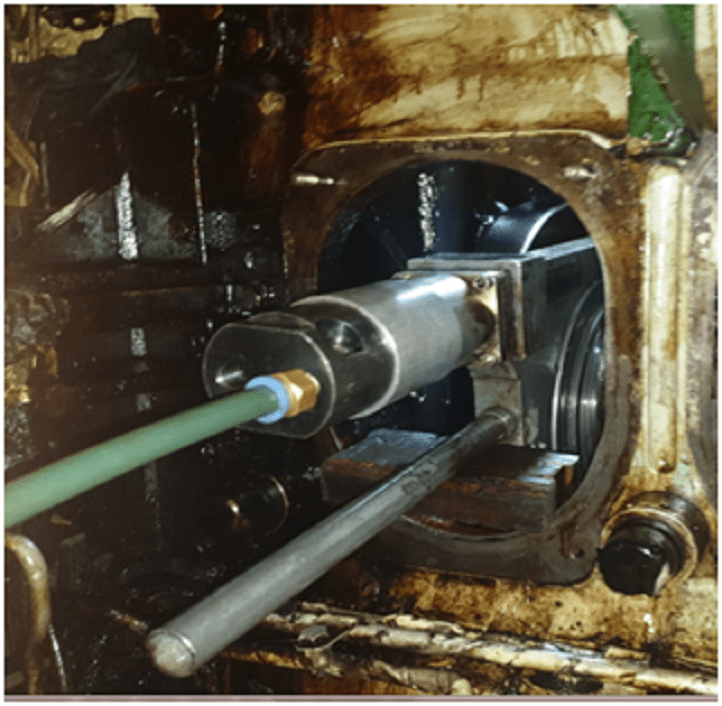

- Our latest design onsite crankshaft grinding machine is inserted from the engine block inspection window and grinding of crankpin is undertaken.

- By application of the latest design of our crankshaft grinding machines, we can maintain closed tolerances in terms of taper and ovality far better than the manufacturer’s specifications and tolerances.

Availability of White Metal Babbitt Bearings or Tri-Metal Bearings

- After undertaking onsite grinding of the crankshaft obviously, undersize bearings are required.

- In case the compressor has white metal Babbitt bearings, we undertake the rebabbitting of bearings in-house. While the grinding of the crankshaft is under process, we start the Rebabbitting of white metal babbitt bearings.

- The final machining and bore diameter of Babbitt white metal is maintained as per the grinding size of the crankpin and main journal.

- In the case of old models of compressors, we also develop and manufacture tri-metal bearings as per the sample.

- We also have associates through whom we arrange the tri-metal bearings for popular make and models of compressors based in different parts of the world.

- Having successfully executed the repair of more than 10,000 crankshafts gives us the confidence of the repair of any crankshaft up to 700 mm in diameter all over the world.

- We have thousands of reports of compressor crankshaft that are successfully repaired by us duly signed, stamped, and appreciated by the client. These reports can be shared on request.

We regularly executive crankshaft grinding of all make including the following compressor

- Makita

- Senco

- ANEST IWATA

- Gardner Denver

- Graham Sulzer

- Hitachi

- Bostitch

- Rolair Systems

- Brehob

- Lufkin

- Zebra

- Ingersoll Rand

- Grasso

- Curtis-Toledo

- Brehob

- General Electric

- Ariel

- Cummins

- Kirloskar

- Samson

- Porter-Cable

- Stanley-Bostitch

- Campbell Hausfeld

- DeWalt

For more information, insitu compressor crankshaft grinding, and repair of the crankshaft of the pump, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Summary

Article Name

Insitu Compressor Crankshaft Grinding | Compressor Crankshaft Repair

Author

Raj Shahani

Publisher Name

RA Power Solutions

Publisher Logo