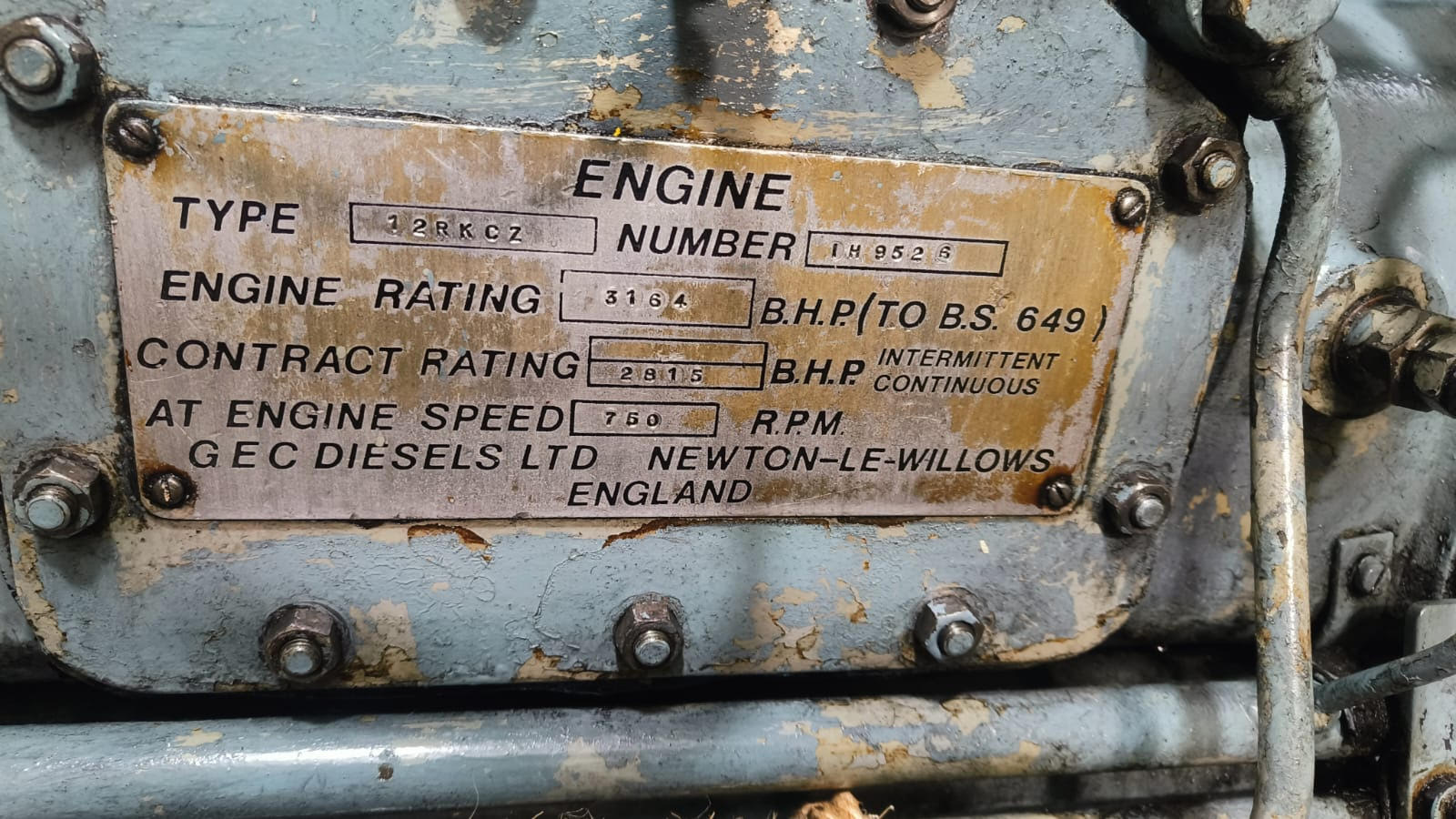

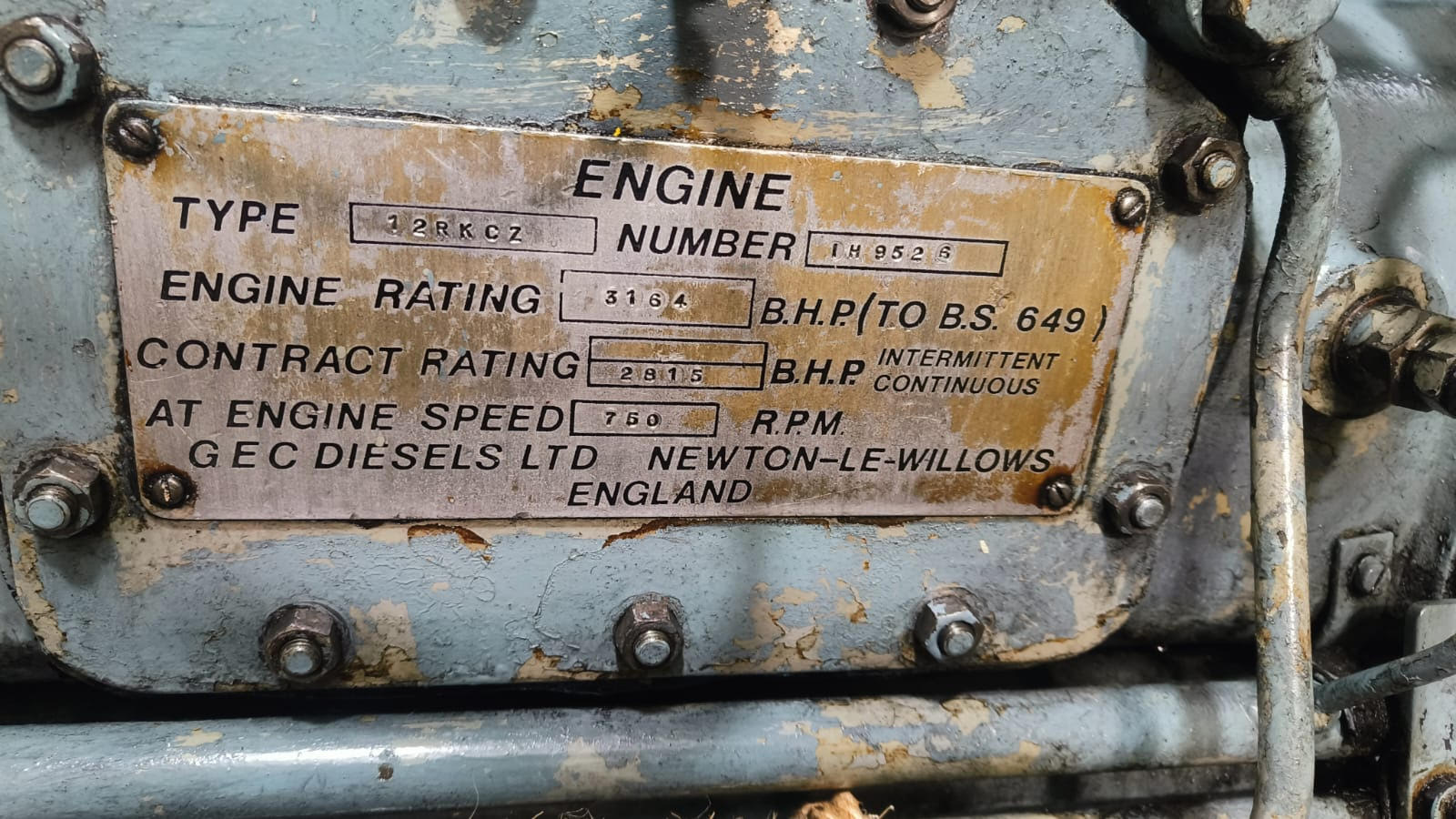

On-site machining of a Ruston 12RKCZ main engine crankshaft was successfully executed by RA Power Solutions at Port Batam, Indonesia. The job was carried out onboard a vessel where all six crankpins of the RUSTON 12RKCZ engine were found damaged, requiring immediate technical intervention.

RA Power Solutions was approached by a leading shipping company based in Indonesia after damage was reported to the crankshaft of their main engine. At the time of reporting, the vessel was anchored at Batam Port, Indonesia, and an urgent on-site repair solution was required to minimize downtime.

|

|

| Damaged Crankpin of RUSTON 12RKCZ Main Engine | Damaged Crankpin Having Line Marks of RUSTON 12RKCZ |

|

|

| RUSTON 12RKCZ Crankpin #03 having line marks | RUSTON 12RKCZ Damaged Crankpin Line Marks |

Action Taken by RA Power Solutions to Repair RUSTON 12RKCZ Crankshaft

(a) Our experienced technicians mobilized with portable onsite crankshaft grinding and polishing equipment, along with calibrated measuring instruments and consumables. The team boarded the vessel and conducted a detailed inspection of the damaged crankshaft of the Ruston 12RKCZ engine.

The details of the engine and crankshaft are pasted below:

| Technical Specifications of RUSTON 12RKCZ Crankshaft | ||

| S. No | Crank Pin Details | |

| 1 | Engine Make | Ruston |

| 2 | Engine Model | 12RKCZ |

| 3 | Crankpin Diameter Standard | 184.00 MM |

| 4 | Crankpin Bearing Width | 81+81 MM |

| 5 | Grinding of Crankpin Number | #01, #02, #03, #06 |

| 6 | Place of Execution of Grinding of Crankpin | Batam |

| 7 | Name of Shipping Company | Reputable Company from Indonesia |

|

|

| Inspection of Crankshaft of RUSTON 12RKCZ | Hardness Test of Damaged Crankpin of Engine RUSTON 12RKCZ |

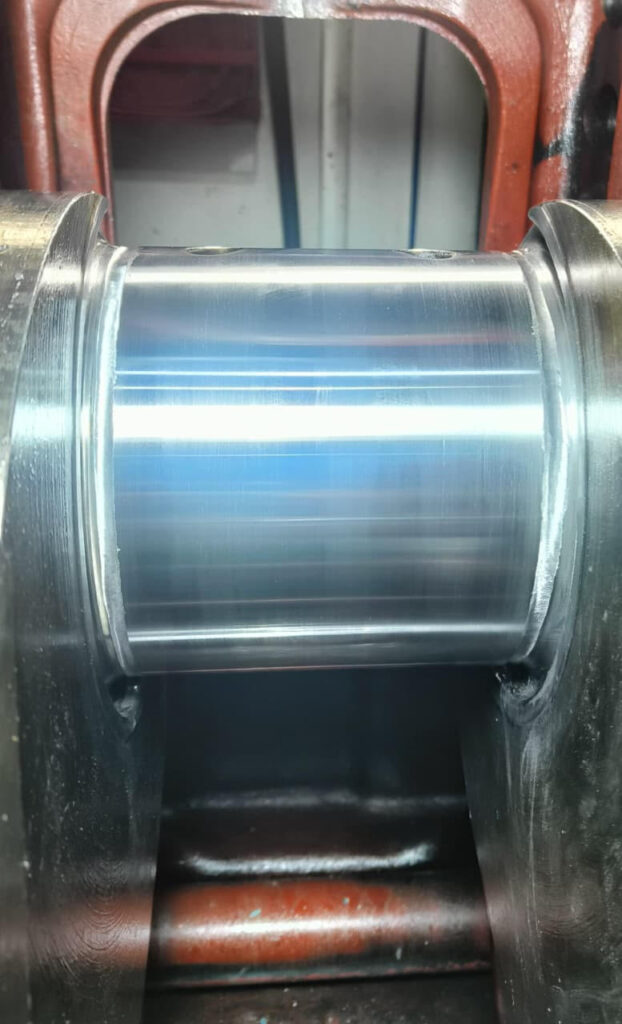

(b) On inspection, the crankpins no. #1, #2, #3 and #6 were found to be damaged, and the remaining two crankpins, #4 and #5, had minor bearing line marks

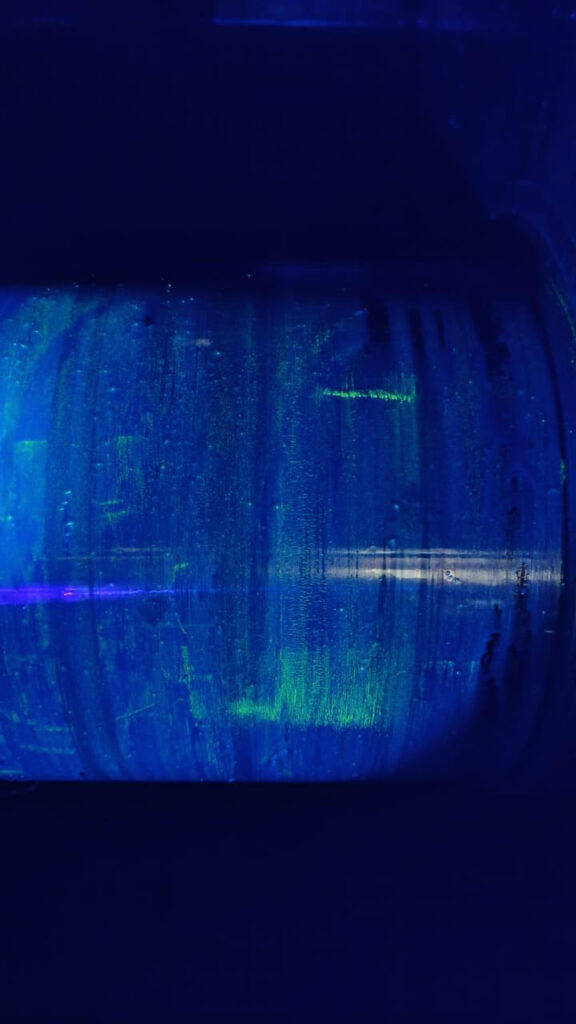

(c) All major parameters, like crack detection by MPI, hardness test, and other inspection procedures, were followed.

(d) In the MPI test, surface cracks were observed on a seriously damaged crankpin. Even the hardness observed was on the higher side.

(e) The grinding of four crankpins was executed, and two crankpins were polished. The final dimensions of crankshaft machining were maintained as follows:

|

|

| MPI Test of RUSTON 12RKCZ Engine Crankshaft | Magnetic Particle Inspection Test of RUSTON 12RKCZ Engine for Crack Detection |

| SIZE OF CR PINS | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 183.57 | 183.58 | 183.56 | 183.56 | 183.58 | 183.57 | 183.56 | 183.58 | 0.02 mm |

| CR-2 | 182.82 | 182.81 | 182.80 | 182.81 | 182.82 | 182.81 | 183.80 | 182.82 | 0.02 mm |

| CR-3 | 183.56 | 183.58 | 183.57 | 183.56 | 183.56 | 183.57 | 183.56 | 183.58 | 0.02 mm |

| CR-4 | Polishing Done | ||||||||

| CR-5 | |||||||||

| CR-6 | 182.50 | 182.48 | 182.49 | 182.48 | 182.49 | 182.49 | 182.48 | 182.50 | 0.02 mm |

(f) After completing the machining process, the client arranged for undersized crankpin bearings from a UK-based manufacturer, which were subsequently installed.

|

|

| Onsite MPI Inspection Ongoing | MPI of Crankpin of RUSTON 12RKCZ |

The following undersized bearings were used:

| S. No | Bearing Type | Maximum Diameter (mm) | Minimum Diameter (mm) |

| (i) | US | 183.616 mm | 183.566 mm |

| (ii) | US | 183.225 mm | 183.185 mm |

| (iii) | US | 182.844 mm | 182.804 mm |

| (iv) | US | 182.463 mm | 182.423 mm |

|

|

|

|

| Onsite crankpin of RUSTON 12RKCZ Repaired |

Worldwide Onsite Machining Services by RA Power Solutions

RA Power Solutions is a global leader in onsite crankshaft repair, grinding, and polishing services, with over 45 years of experience. We execute onsite machining jobs for marine, power plant, and industrial engines worldwide, including locations across Asia, the Middle East, Europe, Africa, and the Americas. Our ability to mobilize skilled technicians with advanced portable equipment enables us to perform critical engine repairs anywhere in the world, minimizing downtime and eliminating the need for crankshaft removal.

With decades of hands-on experience and a presence across power plants, marine engines, oil & gas, and heavy industries, the company is widely trusted for onsite crankshaft grinding services that eliminate costly dismantling and downtime. Using state-of-the-art portable grinding machines, laser-based alignment systems, and highly skilled engineers, R A Power Solution ensures micron-level accuracy, superior surface finish, and extended engine life—right at the customer’s site.

For any information, please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.