One of the major shipping companies based in Singapore approached RA Power Solutions to inspect the crankshaft of Yanmar 6M220L-SN having a crankpin diameter of 170 mm and a crankpin bearing width of 66 mm.

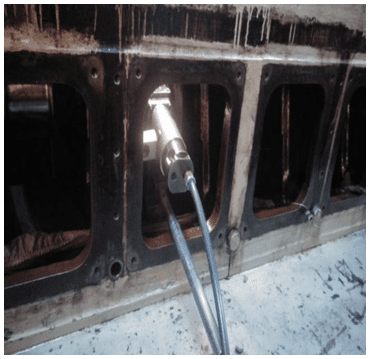

A team of two technicians along with an onsite crankshaft grinding machine capable of undertaking the reconditioning of the crankshaft of Yanmar 6M220L-SN were deputed on the vessel to undertake the inspection and evaluate the extent of damage. The crankshaft was inspected for the following major parameters and inspection reports on RA Power Solutions Pvt. Ltd. Format was prepared.

Steps were taken for inspection and testing of the crankshaft of Yanmar 6M220L-SN

- Inspection of the diameter of all six crankpins for taper and ovality.

- Visual inspection of crankpins to check the damage to radius fillet, lubricating oil hole, counterweight bolts, and adjacent area.

- Hardness testing of crankpins with special attention near the radius fillet and lubricating oil hole.

- Crack inspection by Magna flux and high-intensity torch.

- Deflection reading to check the alignment.

The main observation of the crankshaft of Yanmar 6M220L-SN

| S. NO | Crankshaft Details | |

| 1. | Engine Make | Yanmar |

| 2. | Engine Model | 6M220L-SN |

| 3. | Crankpin Diameter Standard | 170mm |

| 4. | Crankpin Bearing Width | 66 mm |

| 5. | Name of Vessel | M/V PARKER |

- Since all the crankpins had ovality ranging from 0.15 to 0.25 mm. All the crankpins were undersized to the size of 0.4 mm.

- All the parameters including dimensions were checked after the repairs and recorded.

- The undersized bearings were supplied by RA Power Solutions.

- RA Power Solutions Pvt. Ltd. technicians always carry with them the instruments to check the connecting rod’s big end and small end bore and also to inspect the bearing thickness and other parameters. On getting the dimensions and tolerances within limit the engine was assembled and put on a trial load.

- Performance of engine observed satisfactory.

Trust the heart of your engine Yanmar 6M220L-SN crankshaft to the competent and experienced company. RA Power Solutions has the experience, and the necessary equipment to save the heart of the engine i.e. crankshaft.

The brief of facilities available with us is as follows

- Our own designed and manufactured onsite crankshaft grinding machines have diameters ranging from 35 mm to 700 mm. Changes can be made for small bearing widths or space.

- Machine manufactured of titanium alloy absorbing the vibration.

- Grinding and polishing are possible while sailing the vessel.

- The only company in the world undertaking onsite grinding and polishing of the crankshaft designing and manufacturing their tooling and equipment. Experience of forty years saved 10,000 crankshafts all over the world; it’s a record.

- All technicians are trained in-house training school.

- An ISO 9001:2015 certified company has won many awards.

- Maintaining far better specifications after crankshaft repair than engine manufacturer.

- All technicians have a seaman book, no need for a visa, and can board the vessel in the shortest possible time.

- Cheapest in the world. Save the cost of crankshaft repair, and contact the leaders.

For more information, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.