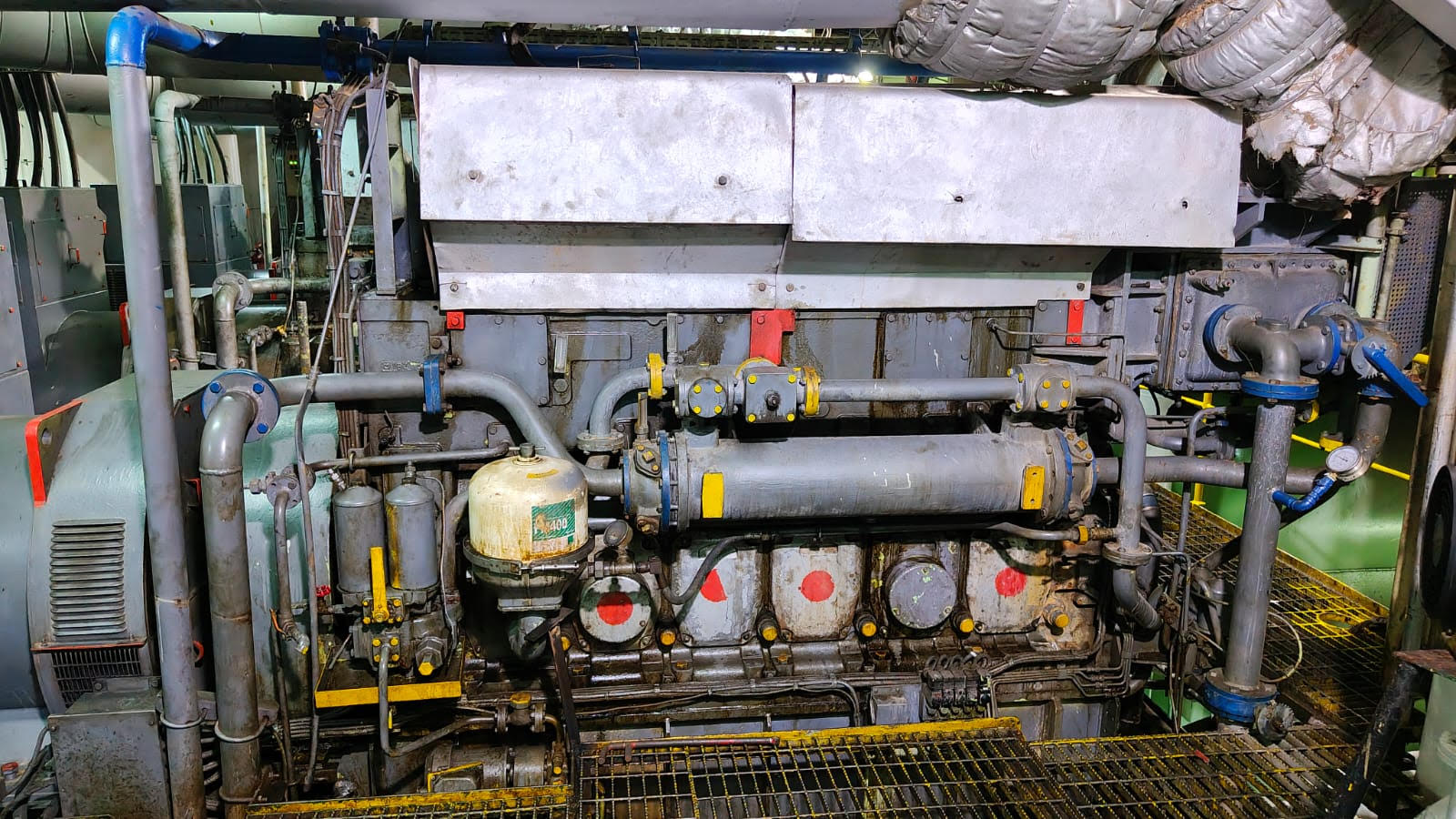

A client operating a container vessel registered in Panama reported damage to the Daihatsu 6DK-20 engine. Our technicians boarded the vessel at Kolkata Port to assess the problem. The engine details are as follows:

| S. No. | Crankpin Details | |

| 1. | Engine Make | Daihatsu |

| 2. | Engine Model | 6DK-20 |

| 3. | Crankpin Diameter Standard | 170.00 MM |

| 4. | Crankpin Bearing Width | 78.00 MM |

| 5. | Grinding of Crankpin Number | #05 |

| 6. | Place of Execution of Grinding of Crankpin | Kolkata Port |

| 7. | Name of Shipping Company | A Reputed Shipping Company Based In Dubai, UAE |

|

|

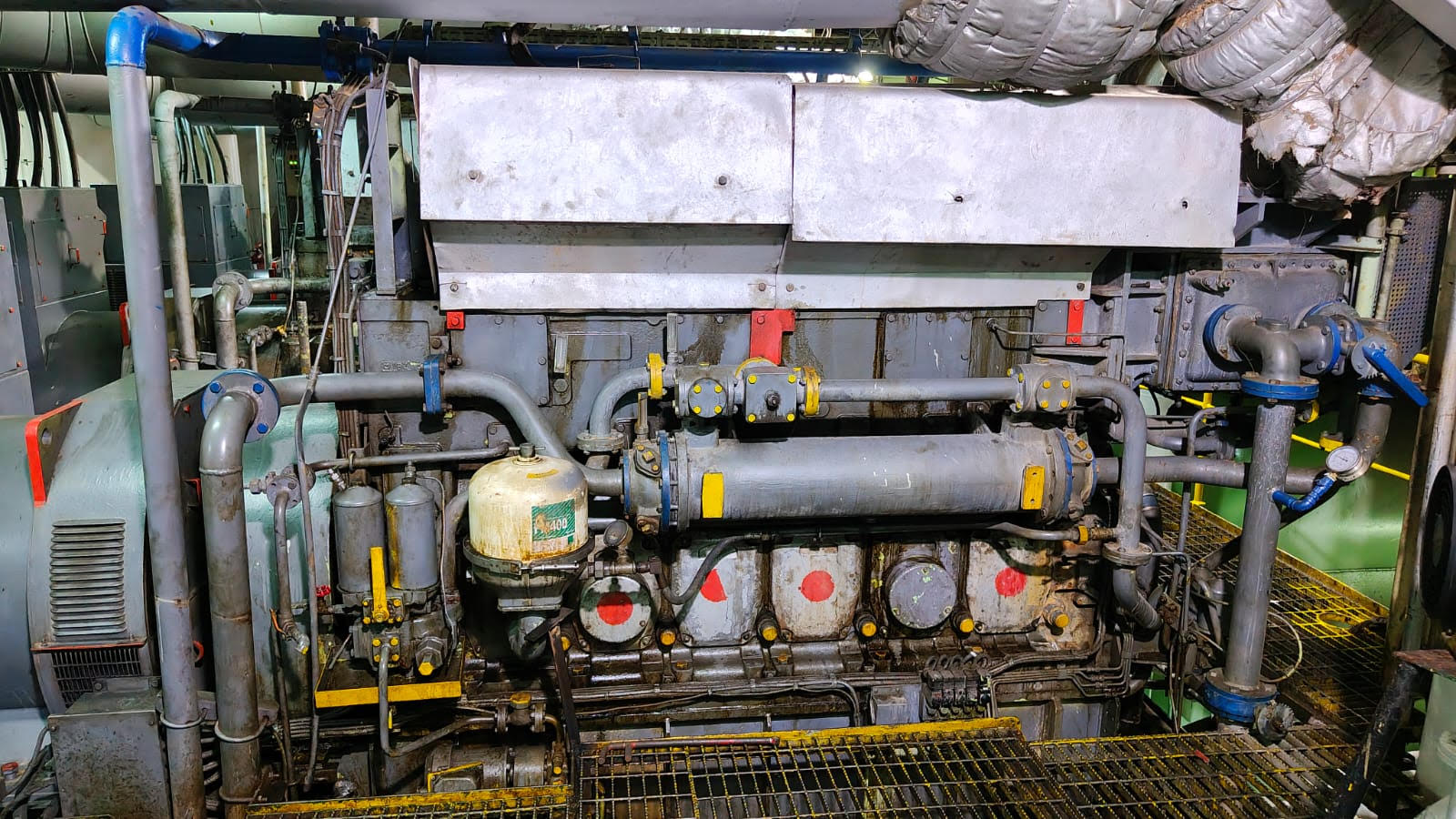

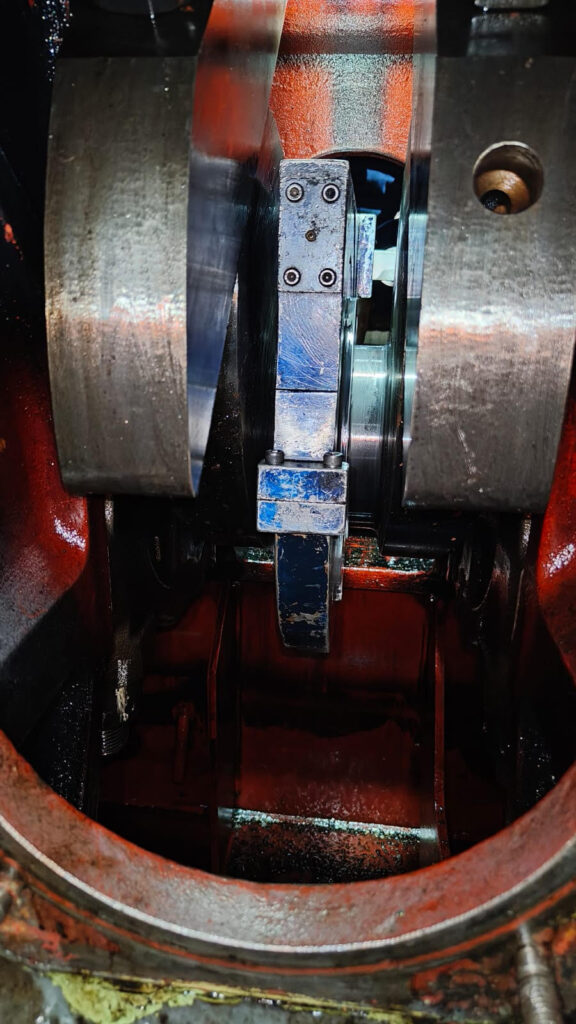

| Damaged Crankpin of Daihatsu 6DK-20 | Daihatsu 6DK-20 Crankpin Before Grinding |

On the visual inspection, the crankpin number #05 was observed to be damaged, and on the dimensional inspection, an ovality of 0.46 mm was observed. The readings are provided below:

| SIZE OF CR PINS BEFORE REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | |||||||||

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | |||||||||

| CR-5 | 169.56 | 169.81 | 169.69 | 169.95 | 169.54 | 169.74 | 169.54 | 176.00 | 0.46 MM |

| CR-6 | |||||||||

|

|

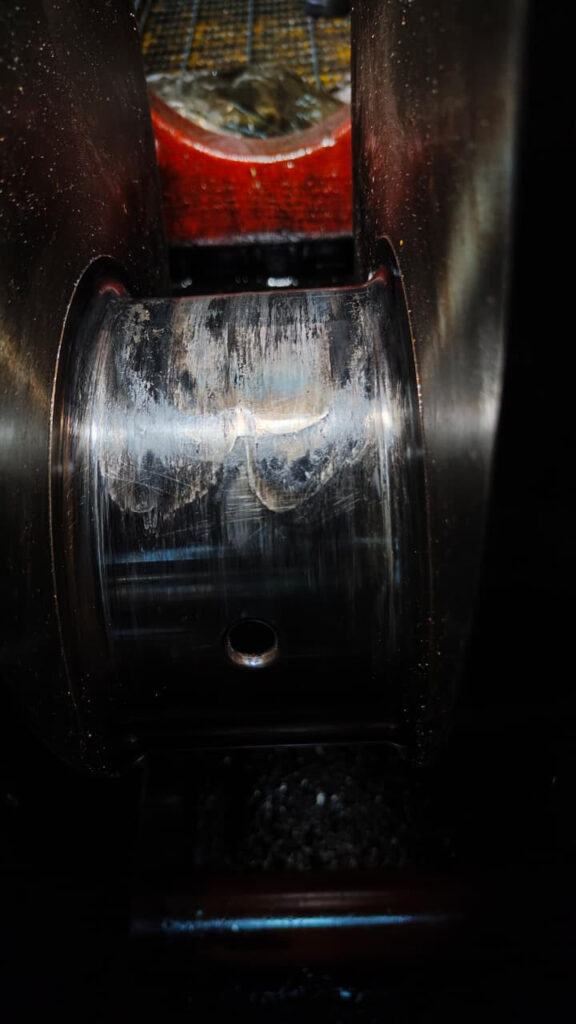

| Crack Detection through MPI | Crankshaft Inspection of Daihatsu 6DK-20 |

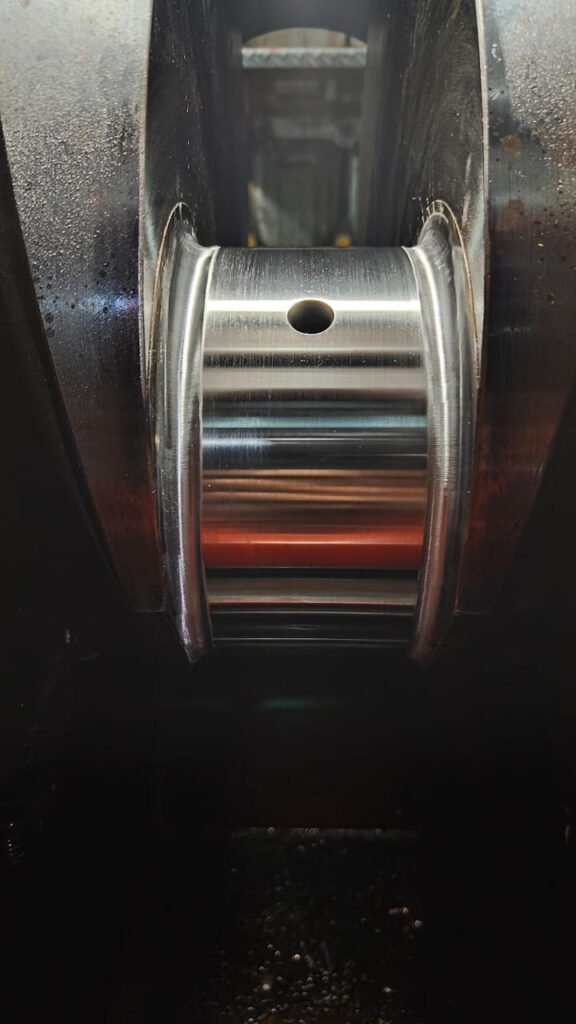

After the pre-inspection of crankpin number 05 of the Daihatsu 6DK-20, as per the protocol, which included dimensional inspection, hardness testing, and Magnetic Particle Inspection (MPI) for crack detection, grinding was initiated, since all parameters were found to be within acceptable limits. The Crankpin Number #05 was undersized by 1.50 MM.

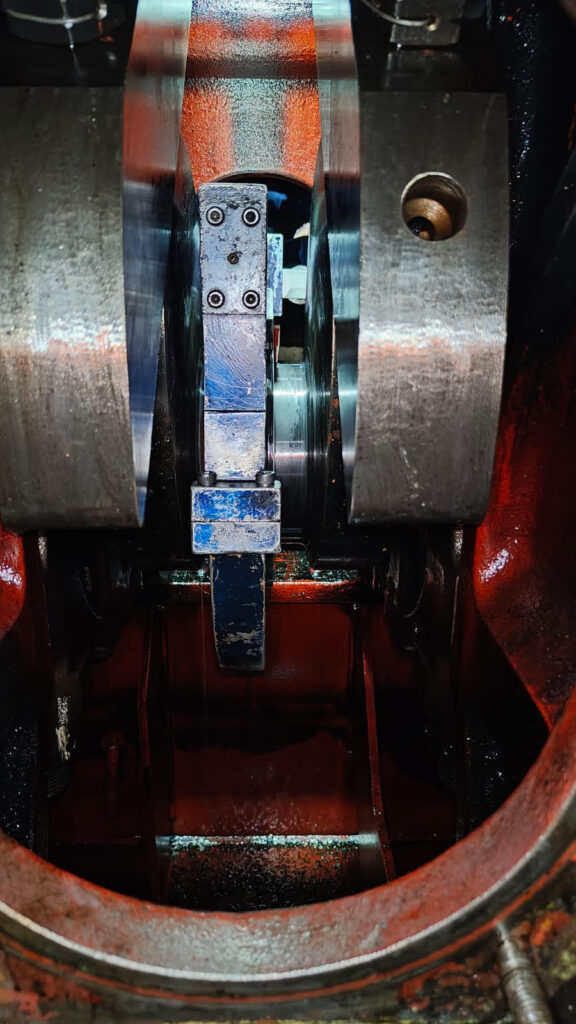

Final dimensions are provided below:

We have to reduce the diameter by 1.5 mm due to deep bearing line marks.

| SIZE OF CR PINS AFTER REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | |||||||||

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | |||||||||

| CR-5 | 168.49 | 168.50 | 168.48 | 168.49 | 168.49 | 168.50 | 168.48 | 168.50 | 0.02 MM |

| CR-6 | |||||||||

|

|

| In situ crankshaft grinding of Daihatsu 6DK-20 engine | Daihatsu 6DK-20 Engine Machining Onsite |

|

|

| Insitu Crankshaft Grinding and Polishing of Daihatsu 6DK-20 | Crankshaft Repairs Under process |

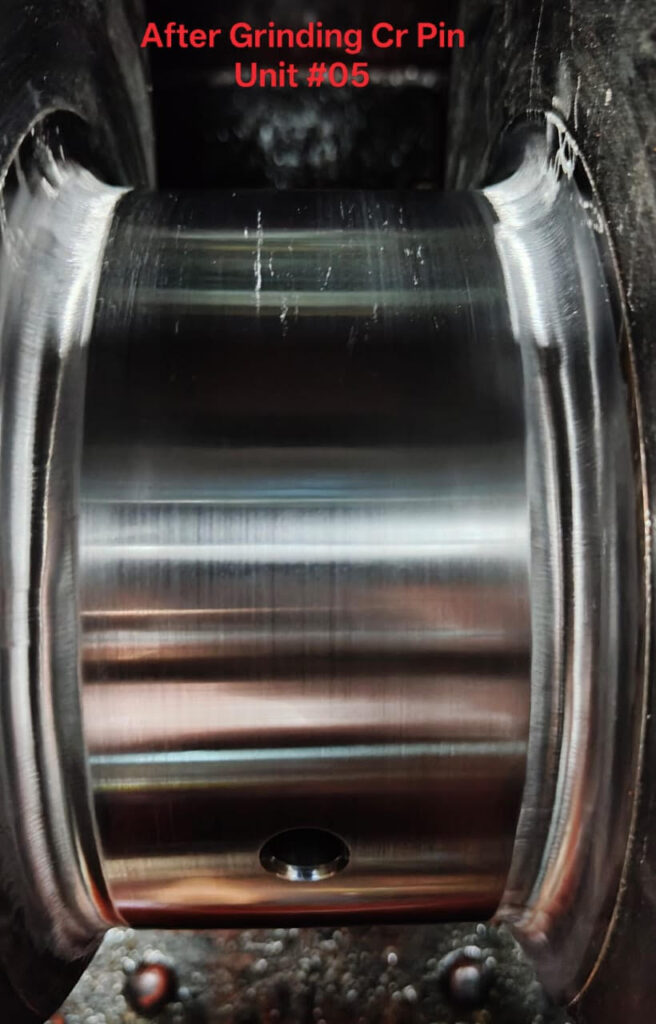

Supply Of Undersized Bearings For Daihatsu 6DK-20

Our technicians carried with them two (2) pairs each of 1.00 mm and 1.50 mm undersized crankpin bearings. The 1.50 mm bearings were fitted, and the engine was put back into operation within a few hours after the crankshaft repair of the Daihatsu 6DK-20 was executed. We maintain a large stock of crankpin bearings for the Daihatsu 6DK-20, as well as for other popular engine makes and models.

|

|

| After Grinding Crankpin of Daihatsu 6DK-20 engine | Crankpin after Grinding and polishing Daihatsu 6DK-20 engine |

RA Power Solutions, with experience of more than 45 years, extends onsite crankshaft grinding services to leading shipping companies, power plants, and heavy industries all over the world.

We have a team of trained technicians available 24/7 and can be deputed on short notice. Some of our technicians also have valid US VISA and can fly to South America, Caribbean countries, etc.

For more information regarding insitu crankshaft grinding, crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.