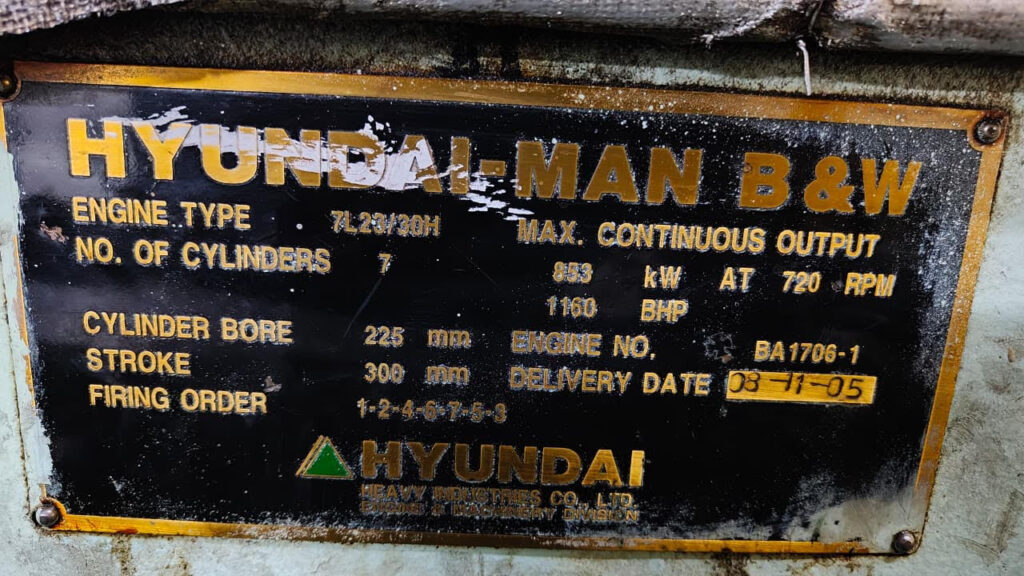

RA Power Solutions has recently executed the in place machining and grinding of auxiliary engine model 7L23/30H MAN B&W at Suez Port. The crankshaft of the MAN B&W model 7L23/30H had a major failure, as all the crankpins were damaged due to the use of inadequate lubricating oil. The operation manual appears not to have followed the protocol for changing the lubricating oil.

Deputation of RA Power Solution technicians to Suez Port:

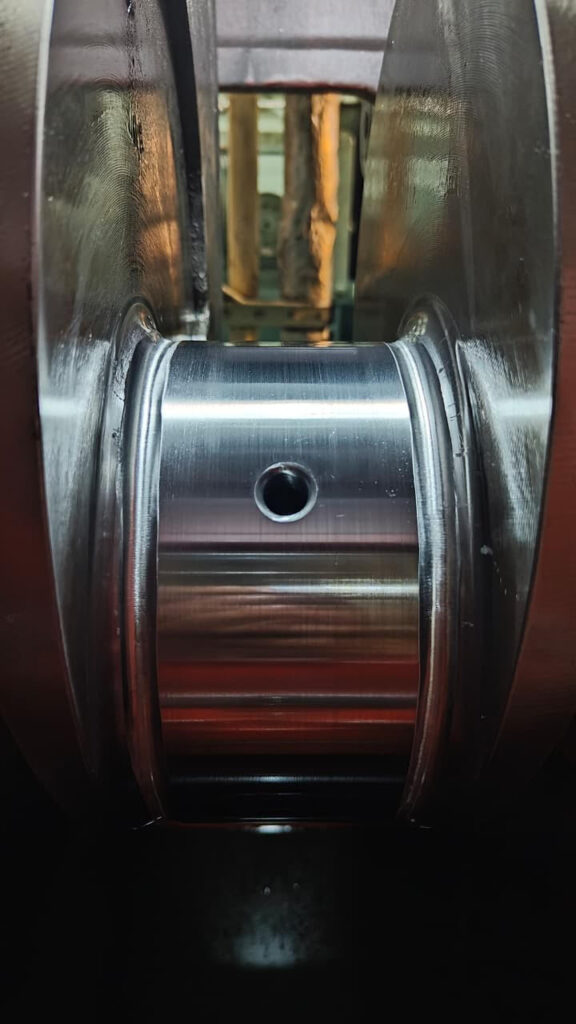

RA Power Solutions deputed two technicians, along with an onsite crankshaft grinding machine and necessary measuring instruments, to Suez Port, where they boarded the vessel. The inspection of crankshaft was conducted as per the RA Power Solutions protocol.

The following are the main observations:

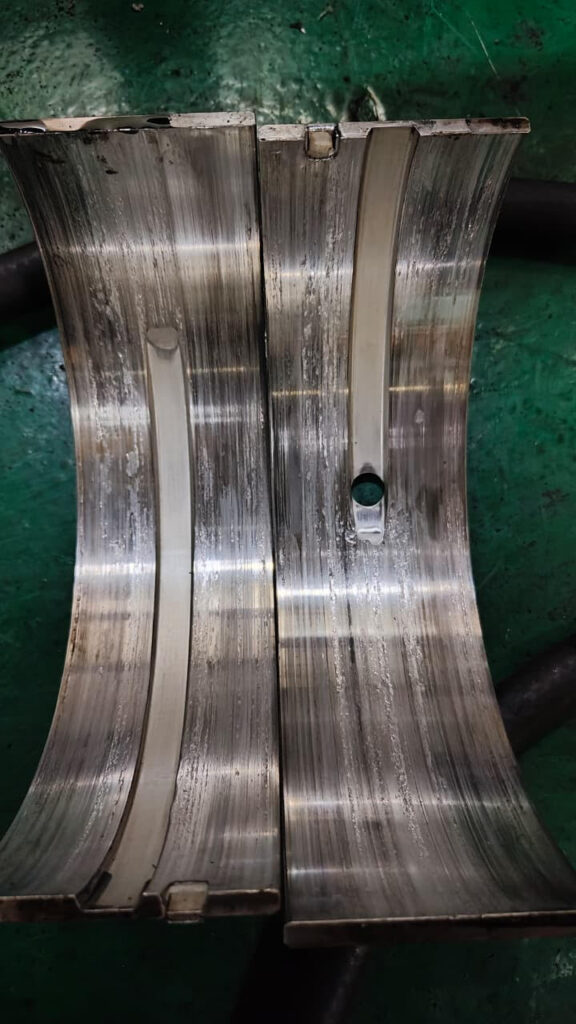

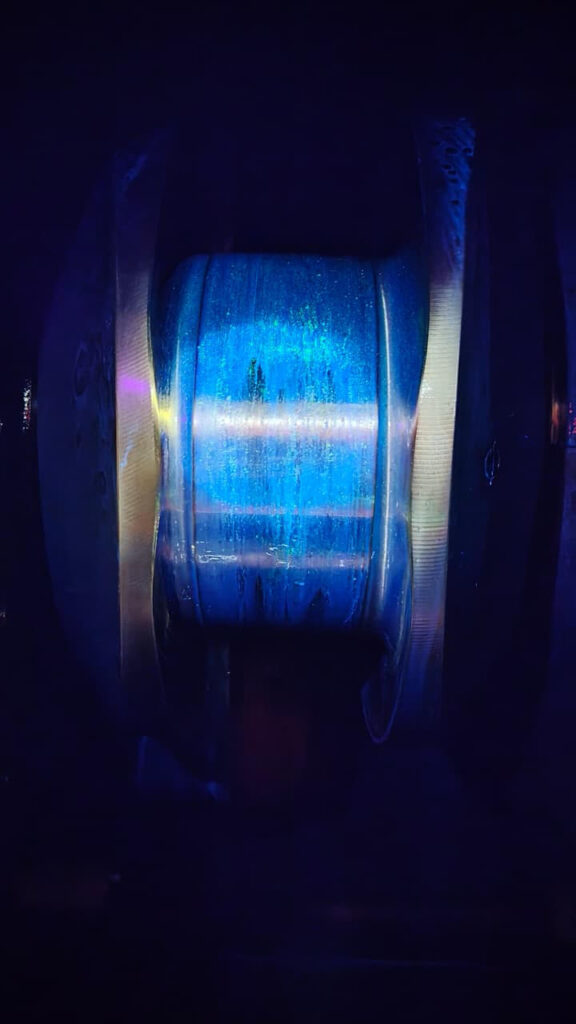

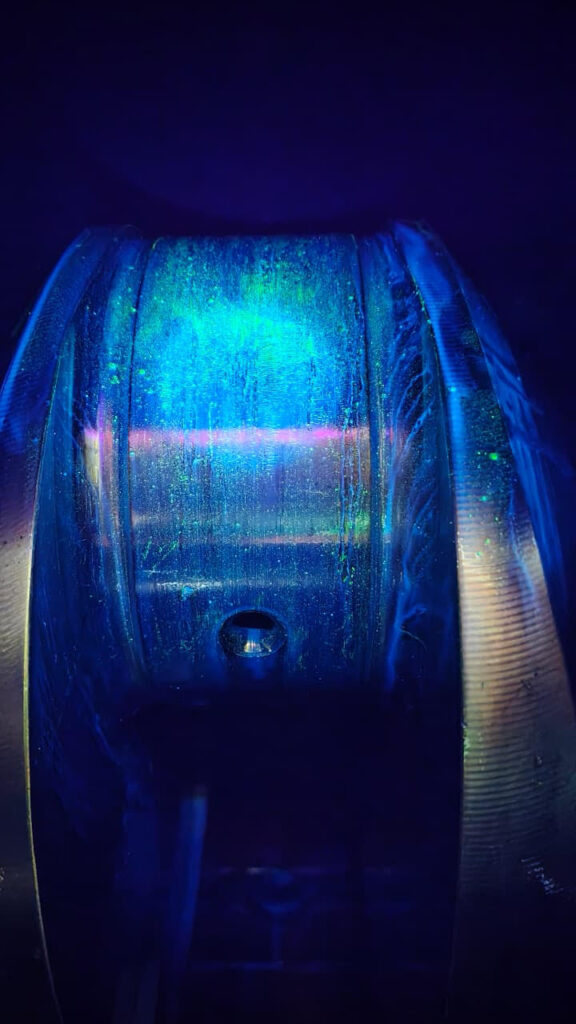

(i) On the visual inspection of the crankpins, it was observed that all seven crankpins were damaged. The bearing material was embedded on a few of the crankpins. The deep bearing line marks and rough surface are also observed.

(ii) The hardness of the crankpin was taken, and no abnormality was observed.

(iii) The crack detection of all seven crankpins was undertaken by the MPI method, and no crack was observed.

(iv) On dimensional inspection of the crankpins, orality in the range of 0.10 mm to 0.26 mm was observed in the case of six crankpins. In the remaining one, a crankpin ovality of 1.40 mm was observed.

The standard details of the crankshaft are as follows:

| S. No. | Crankpin and Main Journal Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 7L23/30H |

| 3. | Crankpin Diameter Standard | 185.00 MM |

| 4. | Crankpin Bearing Width | 70.00 MM |

| 5. | Grinding of Crankpin Number | #01, #02, #03, #04, #05, #06, #07 |

| 6. | Place of Execution of Grinding of Crankpin | Suez Port, Egypt |

| 7. | Name of Shipping Company | Reputed Company from Chennai, India |

Action taken by RA Power Solutions for the successful repair of MAN B&W crankshaft:

(i) Six numbers of crankpins were undersized by 0.5 mm.

(ii) One number of crankpins was undersized by 2.0 mm.

(iii) We strictly maintained all parameters as per the manufacturer’s requirements and the maintenance manual.

Global Onsite Crankshaft Grinding & Crankpin Repair Services

RA Power Solutions is a leading global provider of onsite crankshaft grinding, crankpin repair, and journal machining for marine and industrial engines. With 45+ years of experience, we deliver fast, reliable, and cost-effective crankshaft repair services anywhere in the world—directly onboard your vessel or at your power plant.

Our engineers travel worldwide to execute in situ crankshaft grinding, eliminating downtime and avoiding the costly replacement of damaged crankshafts.

We have successfully completed repair projects in:

Egypt, UAE, Saudi Arabia, Qatar, Oman, Kuwait, Singapore, Malaysia, Indonesia, Turkey, Greece, Bangladesh, Sri Lanka, Azerbaijan, Nigeria, Ghana, and multiple West African regions.

We specialize in restoring crankshafts for major engine brands and models, including:

- MAN B&W: 7L23/30H, 5L23/30, 6L23/30, 6L21/31, 6S35MC, 7S50MC

- MAK: 6M20, 8M20, 6M32, 8M32, 8CM32C

- Daihatsu: 6DK-20, 5DK-20, 6DE-18

- Wartsila: Vasa 12V32LN, 6L32, 9L20

- Caterpillar: G3616, 3508, 3516

- Yanmar: EY18, EY22, 6N165

Using portable, advanced onsite machining tools, we undertake:

- Crankpin grinding & undersize machining

- Main journal grinding

- Ovality & taper correction

- Crack detection (MPI)

- Hardness testing & dimensional inspection

Whether your ship is docked or sailing, we deliver OEM-standard accuracy, restore the crankshaft quickly, and minimize your downtime.

RA Power Solutions continues to be the preferred choice for in place machining and grinding and global crankshaft grinding services, trusted by shipping companies, offshore operators, and power plants worldwide.

For any information, please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.