Successful repair of crankshaft, and crankshaft grinding services is our business. RA Power Solutions Pvt. Ltd. undertakes onsite repair of crankshaft of crankpin and main journal diameter ranging from 35 mm to 700 mm. We have a record of successfully repairing crankshafts number exceeding 10,000 for shipping, power plants, and heavy engineering companies based all over the world. Why approach a crankshaft repair company that has no knowledge, experience, or equipment?

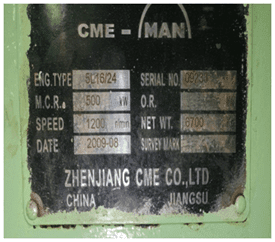

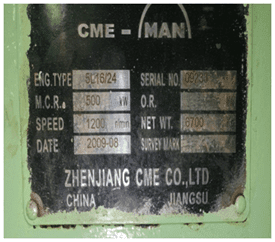

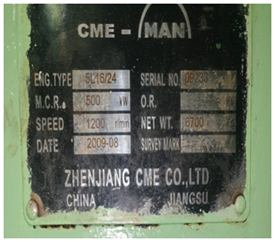

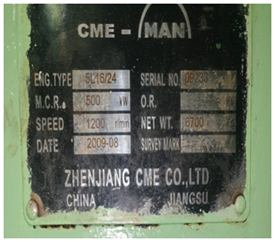

A crankshaft is a piece of art manufactured with close tolerances; it needs expert services to successfully execute the repair. We have repaired some crankshafts that the small and inexperienced companies damaged due to lack of know-how and experience. Recently, we have saved the crankshaft of MAN Diesel Engine Model no. CME 5L 16/24 from rejection.

Following are the details:

Crankshaft repair of MAN Diesel Engine Model No. CME 5L 16/24. Crankshaft Grinding Engine Details Table

| S. NO | Crankshaft Details | |

| 1. | Engine Make | MAN CME |

| 2. | Engine Model | 5L 16/24 |

| 3. | Crankpin Diameter Standard | 130.00 mm |

| 4. | Crankpin Bearing Width | 56 mm |

It was reported by Dubai Dubai-based company that one of their vessel which was sailing near Chittagong port had met with an accident and the crankshaft was damaged. RA Power Solutions. deputed two technicians along with necessary tooling to Chittagong. They boarded the vessel in a short time of 12 hours after receiving the first communication of the breakdown. This was possible as all our technicians have valid Indian CDC.

Following the Inspection of the crankshaft was conducted

- All the crankpins were subject to crack detection by MPI and no crack or abnormality was observed on the crankpin.

- Hardness with a portable calibrated hardness tester was checked and was found within limits.

- The deflection of the crankshaft was within limits.

All the crankpins were checked for taper and ovality out of five crankpins, two number crankpins had the following readings

| S. NO | Minimum Diameter | Maximum Diameter |

| CRNO2 | 128.76 | 129.36 |

| CRNO4 | 128.36 | 128.73 |

Ongoing through the above dimensions, owners were surprised as the damage to the crankpins was beyond the last limit stipulated by the engine manufacturer i.e. MAN Diesel for Engine Model no. CME 5L 16/24. In other words as per the manufacturer, there was no solution but to reject the crankshaft and replace it with a new one.

RA Power Solutions took the following action to save the crankshaft from rejection

- Based on the above readings of crankpin no. 2 and crankpin no. 4, it was decided to undersize the crankpin to 1.5 mm and 2 mm from the standard diameter of 130 mm.

- The grinding was undertaken by our technicians and the final diameter of 128.50 and 128.00 mm was maintained.

- The undersized crankpin bearings of 1.5 mm and 2 mm were arranged by RA Power Solutions.

- The MAN Diesel Engine Model no. CME 5L 16/24 was commissioned and the engine is performing satisfactorily.

The under-sizing of the crankpin up to 2 mm is of course done under deviation and against the manufacturer’s recommendation but the fact is that the crankshaft has been successfully repaired and is saved from rejection which helped the owners of the vessel to save a considerable amount and downtime. We at RA Power Solutions always believe in saving the crankshaft from rejection. The cost of the crankshaft is exorbitant and has no justification by the engine and crankshaft manufacturer who enjoy the monopoly.

RA Power Solutions suggests not engaging companies with no expertise and specialized equipment for the repair of the crankshaft. We have the knowledge, experience, and necessary equipment to undertake the repair.

Crankpin Repair Services

We observed that companies avoid crankpin repair due to the time taken to repair of crankpin and the high cost. This was true as few companies based in Europe and Singapore enjoyed the monopoly and charged exorbitantly for crankpin repair. With the introduction of onsite crankpin repair and main journal repair machine, it is now possible to undertake the crankpin and main journal grinding and polishing in minimal time.

Secondly, the cost of crankpin repair charged by RA Power Solutions is almost one-fourth of the charges of European and other companies. In simple language, crankpin repair has become easy with a low cost. For more information about crankshaft grinding services, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.