In place crankshaft machining and grinding of the MAK-1 8CM32C engine was carried out in Burkina Faso, West Africa, by RA Power Solutions. RA Power Solutions has long been a leader in insitu crankshaft machining and grinding, specializing in the repair of both small and large diameter of crankpins and main journals. The company brings over 45 years of experience in this field.

We have developed a revolutionized tooling which has the capabilities to execute the repairs to close tolerances as stipulated in the engine manufacturer’s manual.

|

|

|

|

|

|

Case Study of Repair of MAK-1 8CM32C Engine Crankshaft In Burkina Faso, West Africa

The major details of the crankshaft of the MAK-1 8CM32C Engine are as follows:

| S. No. | Crankpin Details | |

| 1. | Engine Make | MAK-1 |

| 2. | Engine Model | 8CM32C |

| 3. | Crankpin Diameter Standard | 280.00 MM |

| 4. | Crankpin Bearing Width | 125.00 MM |

| 5. | Grinding of Crankpin Number | #01, #02, #03, #04, #05, #06, #07, #08 |

| 6. | Place of Execution of Grinding of Crankpin | Burkina Faso, WestAfrica |

| 7. | Name of Shipping Company | Reputed Company from Burkina Faso, West Africa |

| 8. | Date Of Execution | 20th August to 10th September 2025 |

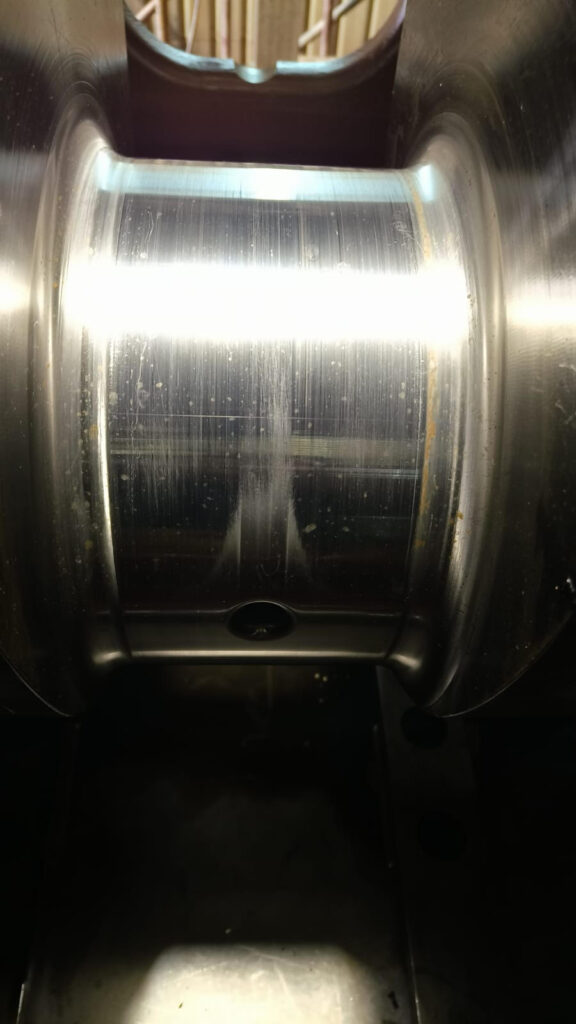

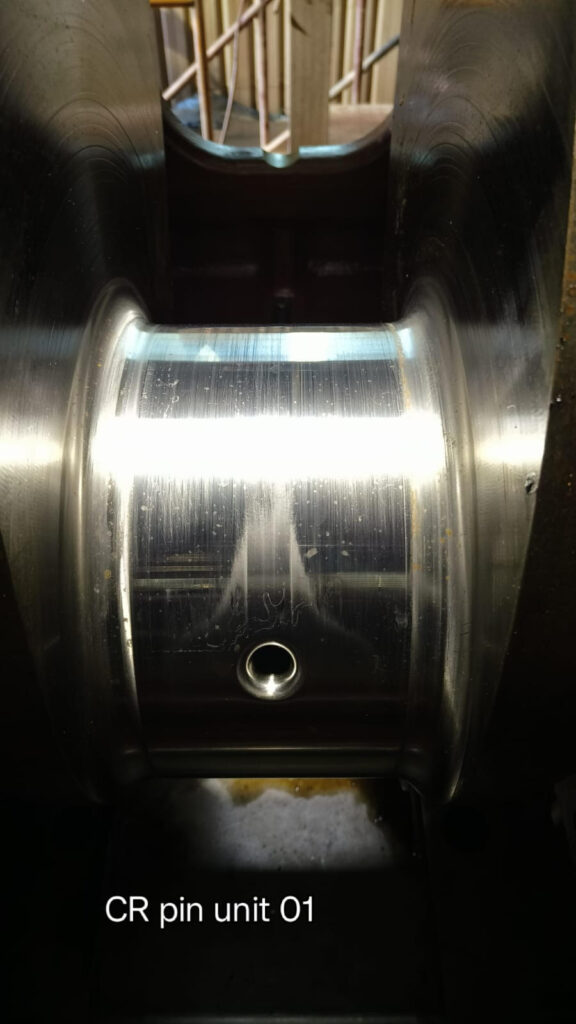

i) Due to the repeated failure of bearings, it was decided by the client to get an audit of the crankshaft for all the major parameters. RA Power Solutions deputed two (2) technicians along with the onsite crankshaft grinding machine from New Delhi to Burkina Faso. During the initial inspection, the following was checked and observed.

a) The dimensional inspection of the crankpins was conducted, and excessive ovality was observed in all the crankpins. The readings for all the crankpins are pasted below:

| SIZE OF CR PINS BEFORE REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 279.89 | 279.95 | 279.90 | 279.90 | 279.89 | 279.93 | 279.89 | 280.00 | 0.11 MM |

| CR-2 | 279.88 | 279.94 | 279.89 | 279.89 | 279.91 | 279.89 | 279.88 | 280.00 | 0.12 MM |

| CR-3 | 279.88 | 279.95 | 279.90 | 279.92 | 279.90 | 279.93 | 279.88 | 280.00 | 0.12 MM |

| CR-4 | 279.88 | 279.95 | 279.89 | 279.92 | 279.90 | 279.91 | 279.88 | 280.00 | 0.12 MM |

| CR-5 | 279.88 | 279.92 | 279.89 | 279.91 | 279.89 | 279.91 | 279.88 | 280.00 | 0.12 MM |

| CR-6 | 279.87 | 279.91 | 279.89 | 279.88 | 279.90 | 279.89 | 279.87 | 280.00 | 0.13 MM |

| CR-7 | 279.88 | 279.95 | 279.89 | 279.94 | 279.90 | 279.96 | 279.88 | 280.00 | 0.12 MM |

| CR-8 | 279.88 | 279.95 | 279.89 | 279.94 | 279.90 | 279.93 | 279.88 | 280.00 | 0.12 MM |

b) As protocol, all the crankpins were checked for hardness by a portable hardness tester and were found within limits.

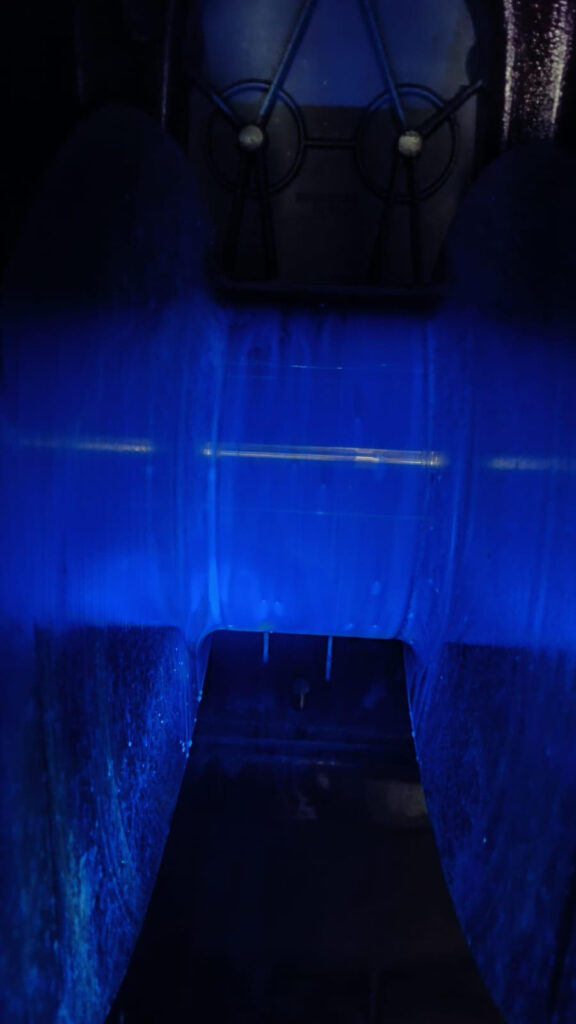

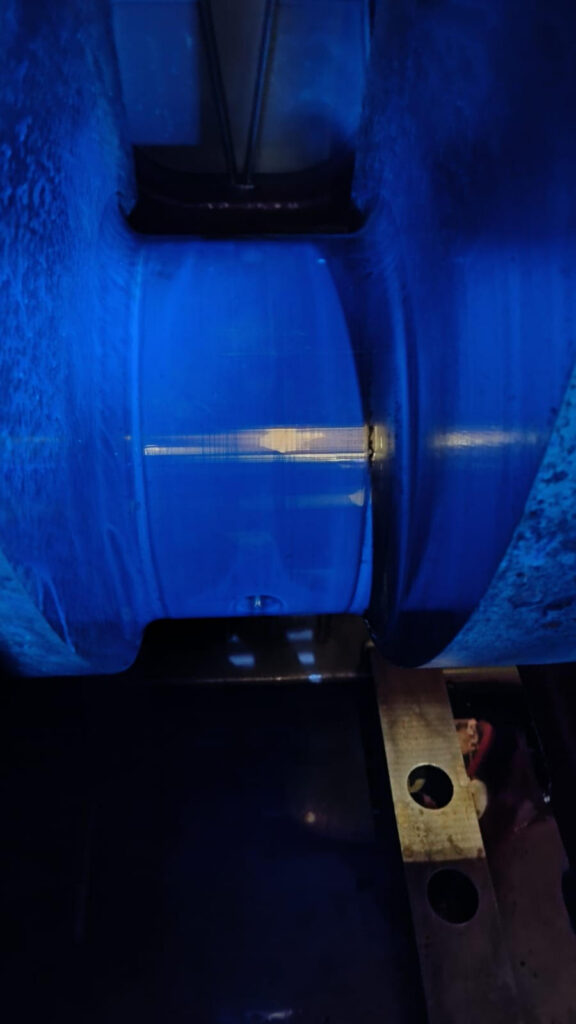

c) MPI was also undertaken to check the cracks, and no abnormality was observed.

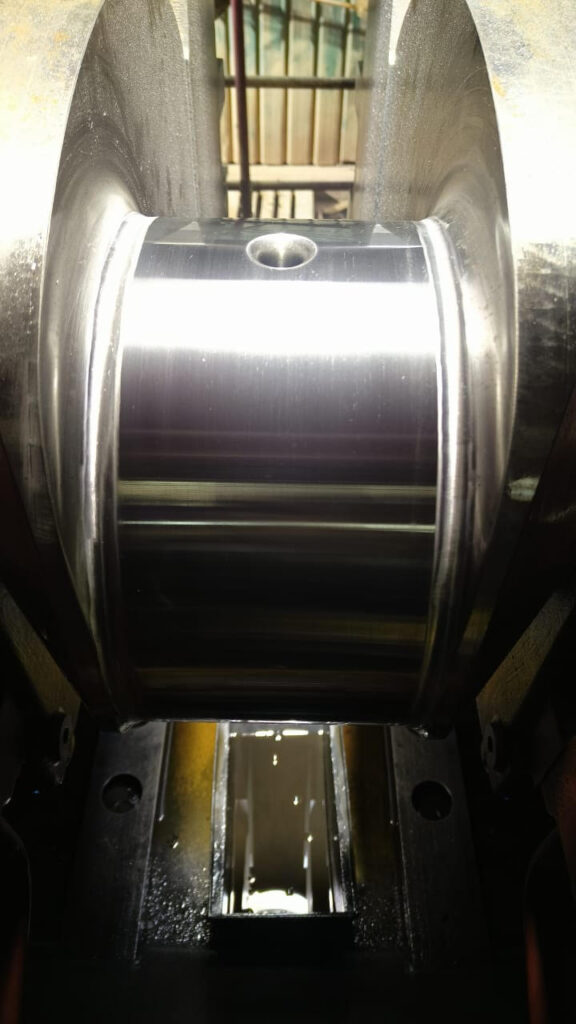

ii) The grinding of all the eight (8) crankpins was executed onsite by our technicians. The first step size and tolerance of 0.02/0.03 MM were maintained.

|

|

|

In Place Machining of Crankshaft of MAK-1 8CM32C Engine

RA Power Solutions has been successfully executing the repair of high-diameter crankshafts up to 700 mm. We also specialize in onsite grinding of small-diameter crankpins with a bearing width of the crankpin as low as 50 mm to execute onsite such types of complex crankshaft repairs onsite. We have developed special-purpose onsite crankshaft machining equipment by which the repairs can be executed. We execute repairs for Marine, industrial, stationary power, and offshore sectors all over the world.

|

|

|

Our technicians are available to travel worldwide on short notice. Additionally, several of our technicians hold valid US visas, enabling them to travel to South America, the Caribbean, and other destinations as needed.

At RA Power Solutions, we provide specialized crankshaft grinding machines, onsite crankshaft grinding repair, insitu crankshaft grinding, Onsite crankshaft grinding machines, insitu crankshaft grinding machines, crankpin bearings, metal stitching, metal locking, engine block repair, crack repair by metal stitching, cast iron crack repair, crankpin polishing, inspection of crankshaft, crankshaft inspection, rebabbitting bearing, babbitt white metal, engine overhauling, grinding of crankpin, connecting rod, and turbine shaft bearing services worldwide, including South Africa, Singapore, Greece, Dubai, Iraq, Iran, Malaysia, Colombia, and Brazil.

For more information regarding crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.